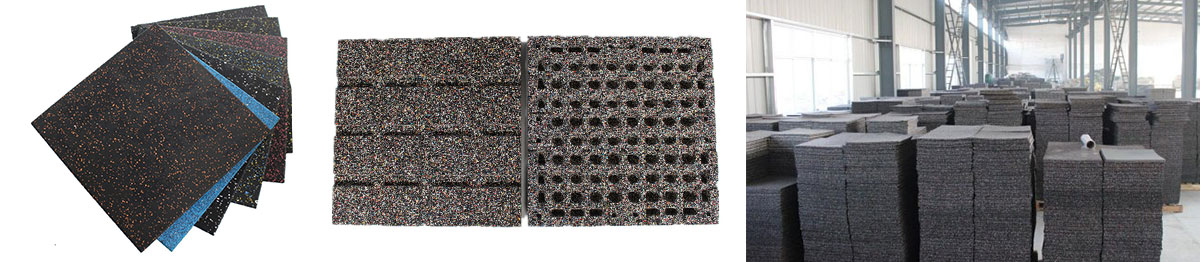

- Mixing Rubber Material for Tile Bottom

We always firmly believe that the best raw materials are the guarantee of quality. After years of selection and testing, we have finally identified a supplier of stable cooperation.

Uniform mixing helps to build a smooth and solid bottom to guarantee the durability.

- Cutting Rubber Rolls for Layers

The layer of Vasto composite rubber tile are all from the highly quality rubber flooring rolls with certain percentage of EPDM flecks. The thickness of the layer ranges from 3mm to

12mm and can be customized for special needs.

-Second-time cut rubber rolls in requested size

The rubber layers will proceed the second cut progess, made it to requested size like 500mm*500mm or 1000mm*1000mm and then it will go for next compositing step.

-Putting Layer on the Bottom for Laminating

The cut layer now is going to the core process in the rubber tile production - compositing, we will take different molds for different tile series: groove base, solid base,

different thickness, etc. Only experienced and skilled workers can operate the machine with right time and temperature control.

- Finished Rubber Tile for Packing

After the laminating process, we will get the tight and strong rubber tile in certain size. After careful packing, they are ready for delivery to our customers all over the wold.